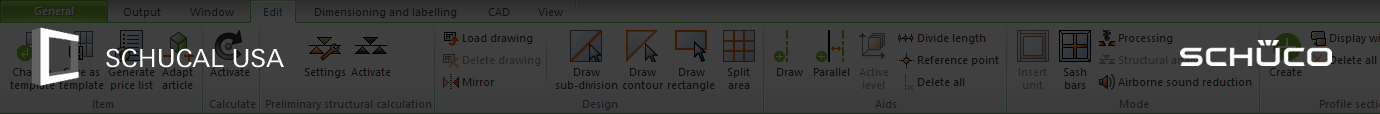

Schucal 2023 R3 – Changes for US market

Some changes have been made to improve program performance with large amounts of data.

Please note:

Due to this, the first program start may take longer with large amounts of data after installing this service pack. In this case, please be patient and do not cancel the starting process.

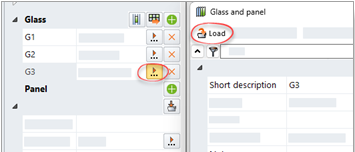

Project glass and project panel:

Changes when loading glass and panels

All glass and panels specifically used in a project are clearly labelled with short descriptions. The short descriptions are generally pre-assigned by the program as soon as a glass or panel is used in a project. The short descriptions can be changed, if required.

Using the Load function, you can change the data for the project glass currently being edited. You can load the data for a glass from the master data or the data for a project glass already in use. Please note the following changes to this function:

- In previous versions, the short description for the loaded glass was also transferred when you went to Load a project glass already in use. This made it possible to replace a project glass with another project glass.

- As of this version, the short description will no longer be included when a project glass is loaded. Only the data will be loaded into the existing project glass. Replacing project glass is therefore no longer possible in this way.

- As of this version, to replace an existing project glass with another available project glass, use the new action button Replace project glass with. This new method only allows you to select from the existing project glasses. When a selected project glass is transferred, all the data will be included, along with the short description. It is not possible to edit this data in the Glass and panel dialog box.

These changes also apply to the loading of project panels, in the same way described above for project glass.

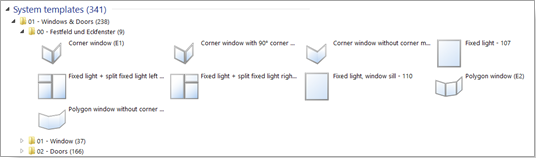

Select template dialog box:

Selecting the system templates for fixed glazing

In the Select template dialog box, all system templates for units with fixed glazing are now provided in a single folder Fixed light and corner window at the start of the folder structure. These templates were previously distributed across the folders for the templates for windows and doors.

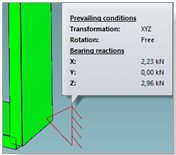

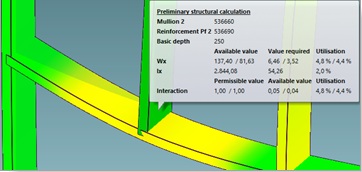

Preliminary structural calculation

Alternative calculation “Global FEM”

Mullion/transom, modular façades (not Schüco FWS 60 CV)

Windows/doors: 2D outline templates (no curved units, no 3D units)

As of this version, the structural preliminary calculation for the profiles can alternatively be calculated on the basis of a new physical/mathematical calculation kernel. This uses the global finite element method (global FEM). In this calculation, the entire unit is considered as a three-dimensional structure of bars.

The result of the preliminary structural calculation includes extended calculations. For example, forces in the longitudinal axes (vertical loads) of the mullions are thus calculated. In the structural analysis mode, the individual bearing conditions and bearing reactions for the façade fixings can be viewed as tool tips.

The situations in the door-head transom area are also considered.

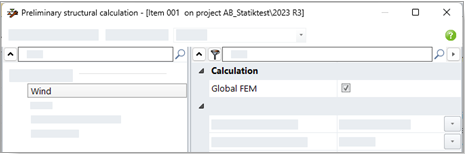

When calling the Structural preliminary calculation dialog box in the item window, you will find the Global FEM check box in the Wind property list under the Calculation group. This setting is only visible for items for which this alternative calculation method can be used.

- If you do not check the check box, the calculation will be performed according to the previous method (calculations as “bar statics”).

- If you do check the check box, the calculation will be performed according to the new method.

New: Country selection “Japan”

As of this version, the preliminary structural calculation can be carried out for Japan. To do this, select Japan from the Select country drop-down list in the Preliminary structural calculation dialog box.

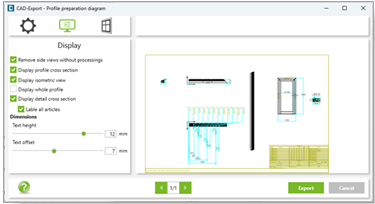

CAD export, profile preparation diagram:

New dialog box with drawing preview

As of this version, the new CAD export – Profile preparation diagrams dialog box opens when exporting profile preparation diagrams. In this dialog box, you will be able to see what the exported drawing will look like before the export begins.

From the tabs of dialog box, you can decide what to export and how the export will displayed. In the preview area, any changes that you make to the settings are displayed simultaneously.

Individual drawing elements can be dragged and dropped, as required.

If you have selected multiple profiles for export, simply flick back and forth between the drawings.

Edit mode:

Transfer to adjoining profile – Improved manipulation

Edits can be transferred to adjoining profiles. To do this, you can check the Transfer to adjoining profile check box for edits.

In the previous versions, you had to set the depth offset value so that the insertion point lies on the adjoining profile. The coordinates, the side and the corner of the original profile were always taken into account.

As of this version, you can, alternatively, also specify that the selection for the sides and corners of the edit are to be adopted by the target profile and that the position for the X and Y coordinates is to be calculated on the basis of the node of the target profile.

To do this, you will find a further Target profile drop-down list when you select Transfer to adjoining profile. In this drop-down list, you can select between Automatic or between the adjoining profiles. If you select Automatic, the function will behave in the same way as previous versions.

Calculation

Contacts:

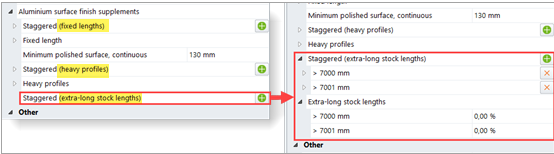

New – Surcharges for coatings of extra-long stock lengths

In the previous versions, it was previously only possible to enter surcharges for fixed lengths that are determined on the basis of their specifications in the optimization settings (fixed lengths that have been calculated through the Optimum order length of the profiles or Manipulate optimization option).

As of this version, surcharges that may be incurred for the coating of extra-long profiles can also be entered in the conditions for the system coater and for your own coaters. In the conditions, new input fields are available for staggered ( extra-long stock lengths) under the Aluminum surface finish surcharges group. There are no default preset values.

Please note that your changes to the master data in the Contacts dialog box can only be transferred to new projects (menu ribbon, General tab > Master data > General > Contacts). If the new surcharges are to apply to a project that has already been created, you need to enter these in the Project properties list in the project window.

As part of this update, the texts for the staggered for fixed lengths and heavy profiles have been changed to improve clarity. The functionality remains the same.

Contacts:

New – Project discount

In the Contacts dialog box, the new Project discount input box has been added under Other for the Schüco system supplier.

The project discount applies to system articles (not for system coating and not for system glass). An entered project discount will be deducted from the calculated price for system articles (after the surcharge, before the special discount and overheads).

Please note that your changes to the master data in the Contacts dialog box can only be transferred to new projects (menu ribbon, General tab > Master data > General > Contacts). If you want a project discount to apply to a project that has already been created, you need to enter it in the Project properties list in the project window.

Windows/doors

Schüco AvanTec SimplySmart and Schüco surface-mounted SimplySmart window fitting:

Update to generation of locking bars

(As of 2023 R2 SP03/SP04)

The generation of locking bars has been changed to match the current K drawing version.

Please note:

This change affects existing items.

Schüco AvanTec SimplySmart and Schüco surface-mounted SimplySmart window fitting:

FSB push-in window handles

The seven new handle models just added to the range – four of which include lockable versions – can be selected for inward-opening windows with a face-fitted vent.

Art. No. 269801 – 269836 & 269838

Art. No. 269843 – 269854

Art. No. 269856 – 269874

Schüco AWS 70.HI and Schüco AWS 75.SI+:

Crack-operated turn/tilt fitting system discontinued

The crack-operated turn/tilt fitting (KDK) is being removed from the range for the aforementioned systems. Therefore, the Crack-operated turn/tilt gearbox handle can no longer be selected for turn/tilt and side-hung opening types.

Any items that you have already entered remain unchanged.

Schüco TipTronic SimplySmart SHEVS bottom-hung windows:

Selecting the fitting version – Text changes

The texts for selecting and generating the fitting version have been changed. The mention of the fitting type has been removed; instead, the fitting version is specified. The opening width is now also mentioned.

Example:

| Old text | New text |

| Type 1, version 1, 400 SK2 | Version 1a, SHEVS opening width 400, SK2 |

Schüco AWS window systems:

Range update, center gasket

The new article numbers for the centre gasket are generated in the program. The change will also affect article numbers for the corner pieces and the gasket frames. Various window systems in the basic depths of 65, 70 and 90 mm (also block systems and windows façades) are affected. Details on exceptions (for example, ventilation vents) can be found in the updated fabrication documents.

| Basic depth | Old | New |

| 65 mm | 246052 | 245752 |

| 70 mm | 246055 278723 | 245755 |

| 90 mm | 284580 | 278735 |

Please note:

This change affects existing items.

Windows and fixed lights across all systems:

Resistance class RC 2 – glazing rebate fixings, gasket cord for burglar-resistant glazing beads

Following the range update to the glazing rebate fixings, the generation of the article numbers and quantities for the glazing rebate fixings and the screws is changing for windows and fixing lights (Technical settings > Glazing > RC 2/RC 2N glazing > Glazing rebate fixing). If you use glazing rebate fixings, the glass used must be rated to burglar resistance class P4A for windows and fixed glazing in order to achieve resistance class RC 2.

The length calculation for gasket cord Art. No. 244058 has also been changed for burglar-resistant glazing beads (K1031539).

Please note:

This change affects existing items.

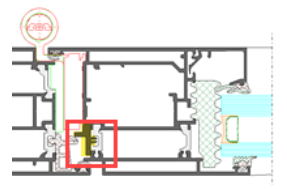

Schüco AWS 75.SI+ and Schüco AWS 90.SI+ in the “optimized” system version:

Changes

The following changes affect units in the “optimized” system version.

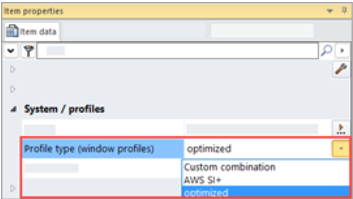

Easier to enter profile filters.

As of this version, units in the “optimized” system version can be entered more easily. In the Item data tab, you will find the new Profile type (window profiles) selection under System / profiles group. Here you can choose between Custom combination, AWS SI+ or optimized.

If you select Custom combination, all the profiles will be available for selection in the drop-down lists. This is the default setting. Existing items remain unchanged.

If you select AWS SI+, no profiles with the optimized contour will be shown in the drop-down lists.

If you select optimized, only profiles with the optimized contour will be shown in the drop-down lists.

The filter applies both to the selection of frame profiles in the Item data tab and to the selection of vent profiles in the Field properties dialog box.

Please note:

The selection will only filter the drop-down lists. Changes will not automatically apply to the profiles already in use.

Resistance class RC 2 – Glazing

The glazing for openings rated to resistance class RC 2 is to adhere to the new glazing table for the glazing rebate gasket Art. No. 284333 used exclusively in the “optimized” system version.

Please note:

This change affects existing items.

Schüco AWS 75.SI+/AD UP 75/ADS 75.SI:

New panic leaf Art. No. 541670 – Schüco AD UP doors

As of this version, for the use of double-vent, outward-opening doors with the full panic function versions, the new door leaf Art. No. 541670 (three-chamber profile) can be selected for profile types AD UP and AD UP BL.

The new door leaf can only be used in the aforementioned systems with AWS attachment; it cannot be used in the Schüco UP 75 and Schüco AD UP 75 BL door systems on their own.

Schüco AD UP doors:

Design door handle upgrades

(As of 2023 R2 SP04)

The following upgrades have been made to Design door handles for doors:

- Pull grip profiles in Schüco AD UP 75

(Schüco AD UP 75, Schüco AD UP 75 BL, Schüco AWS 75.SI+/AD UP 75/ADS 75.SI)

For single-leaf doors, the pull grips can now be entered in accordance with the current order and fabrication documents.

To this end, the operating types Design, Design and comfort and Design and Fingerprint Easy are available for selection in the Field properties dialog box.

- Pull grip profiles with integrated Fingerprint Easy

(Schüco AD UP 75, Schüco AD UP 75 BL, Schüco AWS 75.SI+/AD UP 75/ADS 75.SI, Schüco AD UP 90)

In the aforementioned systems, it is additionally now also possible to select the new operating type for the Design with integrated Fingerprint pull grip profile.

The pull grip profiles Art. No. 546600 and Art. No. 564610 are thus generated for the Fingerprint Art. No. 263800 integrated into the pull grip.

Selecting the type of panel fabrication

As of this version, for the operating types with a pull grip, the additional property Panel fabrication is now displayed under the Design components group. If, alternatively, the door infill can be fabricated by the customer with the used pull grip, you can select this option from the drop-down list. If this alternative is not available, only the information on panel fabrication is displayed (panel from the panel supplier).

Please note:

The type of panel fabrication will determine how the articles for the used panel are calculated and ordered.

- If you select Panels to be fabricated by the customer, the articles required for panel fabrication are indicated in the lists, calculated and output in the order.

- If you select Panels from the panel supplier, the articles required for panel fabrication are not indicated in the lists and are not calculated; they are only output in the order to the panel supplier.

Drawings for panel fabrication

As of this version, the pull grip is also shown in the drawings in the Glazing/panel plan and in the Glazing/panel composition. If you check the Drawing for custom panes / stepped insulating glass option, the pull grip is also shown in the Material list.

Your settings for outputting the double-sided leaf-enclosing door infill will determine whether the infill dimensions (similar to stepped insulating glass) or the sheet cuts (inner and outer infill separate) are shown. (Output tab > Settings group > Output options button > Lists > General > Glass/panel drawings).

Schüco AD UP doors:

New rebate gasket Art. No. 224683

A new rebate gasket Art. No. 224683 has been added to the range. The previous rebate gasket Art. No. 278156 can be generated as an alternative to the new rebate gasket.

In the technical settings, you will find the new property AD UP door rebate gasket under the Gasket group. Here you can choose between Standard (Art. No. 224683) and alternatively (Art. No. 278156). The default setting is Standard.

Please note:

This change affects existing items. The new rebate gasket is now generated instead of the previous rebate gasket.

Please also note the following for the generation of gasket corners:

As of this version, for doors in the Schüco AD UP systems, you can decide whether or not you want to generate gasket corners under the new technical setting Moulded corner for AD UP door rebate gasket. In previous versions, this was specified through the Rebate gasket setting.

For doors in the Schüco AD UP 75 BL system, the setting for the Moulded corner for rebate gasket property remains the same as in previous versions.

Schüco AD UP doors:

Rebate profile for centre gasket

New polyamide articles have been added to the range (Art. No. 270813 (basic depth 75 mm) and Art. No. 270814 (basic depth 90 mm)).

You will find the new property Rebate profile for centre gasket in the technical settings under the Type group. Here you can choose between Polyamide and EPDM. The default setting is polyamide.

Please note:

This change affects existing items. The polyamide article is now generated instead of the previous EPDM article.

Schüco AD UP doors:

Extension profiles with face widths 34 mm, 44 mm and 54 mm

For units in the Schüco AD UP systems, the following articles can now be selected as extension profiles:

- Basic depth 75 mm:

Art. No. 382080

Art. No. 382090

Art. No. 382100

- Basic depth 90 mm:

Art. No. 441010

Art. No. 441020

Art. No. 441030

Schüco AD UP 75:

Barrier-free level threshold now also for double-leaf doors (outward-opening)

As of this version, the barrier-free level threshold can now also be selected for double-leaf doors with a continuous leaf and automatic door seal (resistance classes Standard, RC 2N and RC 2).

If the automatic door seal is selected, the selection for the variants can be found in the Field properties dialog box under the Door threshold property.

Schüco Door Control System (DCS):

“SmartTouch” DCS configuration

(Not available in all countries.)

As of this version, for new items, you will find the With SmartTouch entry again in the Field properties dialog box > DCS components group > DCS configuration property for doors with a DCS profile.

The new 14-pole articles can be selected as cable link connectors: Art. No. 263501 (opening angle of 110 degrees) or Art. No. 263502 (opening angle of 180 degrees).

In the Additional security drop-down list, you can specify whether you want the following articles to be generated: NetProtect (Art. No. 263447) and/or DoorProtect (Art. No. 263446).

Schüco AD UP door fitting:

Latch strikers – Range upgrade, large PU (x100)

The following articles are also available in large PUs (x100) as an alternative to the previous small PUs (x10):

| Basic depth | Small PU | New: Large PU |

| 75 mm | 279464 | 279930 |

| 90 mm | 240566 | 279929 |

| 90 mm | 279465 | 279931 |

Schüco AD UP 75 BL:

Automatically generated processes (MCO): Ventilation and drainage

As part of our efforts to continually improve quality, processes for ventilation and drainage have been fully revised and additional processes have been added. All processes will be automatically generated in accordance with the K drawings.

Please note:

As part of this revision, the processing settings for this system now only contain options for the Spacing and the Minimum field size for the processes in the outer frame. All other previous options under the Drainage/ventilation group have been removed.

The changes also affect existing items.

Schüco AD UP 75 and Schüco AD UP 75 BL:

New technical setting for “window vent” drainage/ventilation

In the technical settings, the settings for Window vent have been expanded (Drainage/ventilation group). As a result, it is now possible to deselect the processes for drainage and ventilation in sidelights, if required.

Schüco AD UP systems:

Technical setting for “transom” and “door transom” drainage/ventilation removed

In the technical settings, the drop-down lists for Transom and Door transom under the Drainage/ventilation group have been removed.

These processing options were inconsistent with the system specifications. According to the technical specifications, drainage and ventilation are provided through the T-joint with the laterally adjacent profiles. Additional processes are not necessary.

Please note:

This change affects existing items if you had previously selected any of the options in question.

Schüco ASS 39 PD.NI:

New locking point with turn knob, new structural profiles

(As of 2023 R2 SP02)

The turn knob (258355, 270046, 270047) can now be selected as an additional alternative to the current locking point. This turn knob can be used on movable vents that do not run on the outside. This new locking point can only be used in conjunction with the new structural profiles 550910 and 550920. To this end, a new entry option has been added in the Field properties dialog box:

With the SLF interlock section profile, you can select the new entry Structural profile on inside, small, for turn knob in the Reinforcement drop-down list. The new structural profiles will then be used; for the handle, you can select the article number you would like for the turn knob.

As part of this new version, the processes for these new articles are now also generated automatically.

Schüco ASS 50 and Schüco ASS 50.NI:

Generation of roller carriages corrected

Discontinued roller carriages were automatically generated for units. This has been changed.

For the 300 kg fitting, Art. No. 276736 is now generated.

For the 150 kg fitting, Art. No. 276735 is now generated.

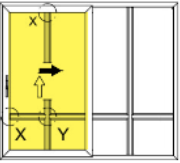

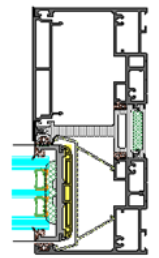

Schüco ASS 50, Schüco ASE 60/80.HI and ASE 80 LC:

Closing assistance – Handle damper and tension spring

(As of 2023 R2 SP05)

In accordance with the amended technical specifications, handle damper Art. No. 281214 is now always generated for lift-and-slide versions. From now on, it cannot be deselected in the program.

In the Field properties dialog box, the only selections now available for the Closing assistance are With handle damper and With handle damper and tension spring. The previous options With tension spring and Without handle damper and tension spring are no longer available.

For vent weights from 100 kg to 350 kg, the With handle damper and tension spring option is automatically generated; for smaller and larger vent weights, the With handle damper is automatically generated.

Please note:

This change affects existing items.

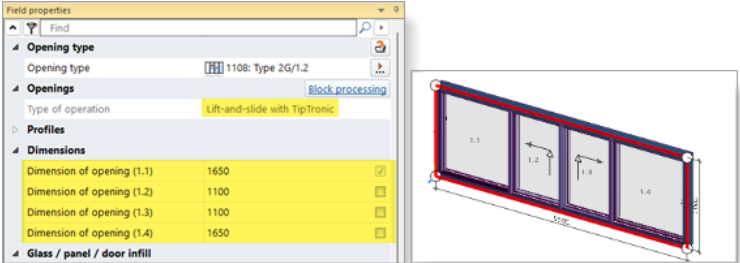

Schüco AS PD 75.HI:

TipTronic operating type – Asymmetric vent subdivision

Asymmetric vent subdivisions can now also be implemented for units with the TipTronic operating type.

Schüco AS PD 75.HI:

Brush seal now only in black

As of this version, the brush seal is always generated in black (Art. No. 203540). The alternative option for the grey seal (Art. No. 224497) has been removed from the technical settings.

Please note:

This change affects existing items. If you had selected the grey seal in the technical settings, the black seal will now be generated.

Schüco ASE 60, Schüco ASE 80.HI:

New vent sash bars

Since 2022 R3 SP01, we have advised that sash bars should only be used under certain conditions. This limitation has now been resolved, as follows:

As of this version, the following new vent sash bar articles are available for selection.

- Art. No. 552290 (ASE 60)

- Art. No. 552300 (ASE 80.HI)

The previous sash bar profiles are no longer available for selection for movable and fixed vents.

Please note:

This change affects existing items. The sash bars previously used in vents will be automatically changed to the new sash bars. This may also result in changes to glass dimensions if sash bars with a 92 mm face width were previously in use.

The change does not apply to fixed lights of the single-track type. In this case, the previous sash bars can still be used.

Schüco ASE 60, Schüco ASE 80.HI:

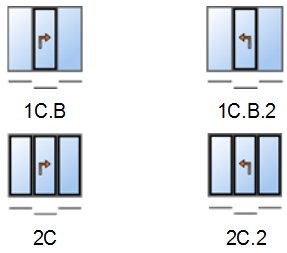

Types 1C and 2C (lift-and-slide) with level threshold not able to be combined with a resistance class

In the previous versions, the aforementioned types with a level threshold and the Lift-and-slide operating type could be combined with a fittings type with a resistance class. As of this version, this combination is no longer allowed. Only the Standard fittings type can still be selected for this combination.

Please note:

This change affects existing items. If a fittings type with a resistance class had previously been selected, it will be automatically reset to the Standard fittings type.

Schüco ASS 77 PD.HI:

Entry profile changed

As of this version, in accordance with the amended order and fabrication documents, the new entry profile Art. No. 284627 will be generated instead of Art. No. 284818. This change affects your existing items.

Please note:

The change does not apply to units in the Schüco ASS 77 PD.HI manual system. The entry profile Art. No. 284818 will continue to be generated for these units.

Schüco AS FD 75:

90 mm face width – Glass thicknesses of 39 mm and 40 mm

In this folding sliding system, with a face width of 90 mm, it is now also possible to use glass thicknesses of 39 mm and 40 mm.

Schüco AS FD 75 and AS FD 90.HI:

Glazing options for RC 2 and PAS 24 vent profiles

(As of 2023 R2 SP05)

For types (inward-opening) that correspond to the specifications in the fabrication documents, the RC 2 or PAS 24 fittings type can be selected. The glazing tables have been changed for this fitting.

The maximum possible glass thickness has been limited, and the 4 mm push-in glass gasket and (to some extent) the 5 mm push-in glass gasket are no longer used.

Please note:

This change affects existing items if they contain a glass of a thickness that is no longer allowed.

Schüco AS FD 75 and AS FD 90.HI:

Maximum unit width instead of a limit on the number of folding vents

Previously, when a custom vent combination was entered, the maximum number of folding vents was limited to 9 per side. This limit has been removed. Instead, as of this version, the maximum unit width of 9000 mm is automatically checked. You will receive a notification if this dimension is exceeded.

Schüco ASS 70 FD and Schüco ASS 80 FD.HI:

Technical settings for roller carriages removed

Under the Fitting group, there were settings for alternative generation of roller carriages. These settings were only valid for existing items from older versions before 2020 R2. Alternative plastic rollers are no longer available for the systems. Now, stainless steel rollers are always generated, even for the old items. The properties Schüco ASS FD roller carriage and Roller carriage/roller carriage hinge have been removed.

Across all systems:

Resistance class RC 2 – Gasket cord for burglar-resistant glazing beads

The length calculation for gasket cord Art. No. 244058 has been changed for the burglar-resistant glazing beads (K1031539).

Please note:

This change affects existing items.

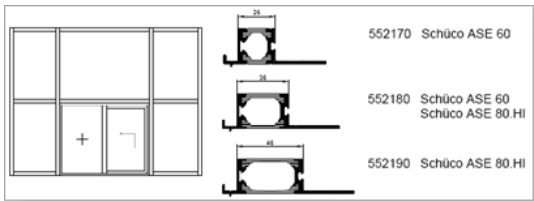

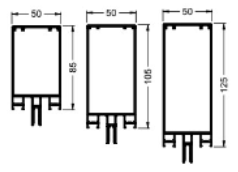

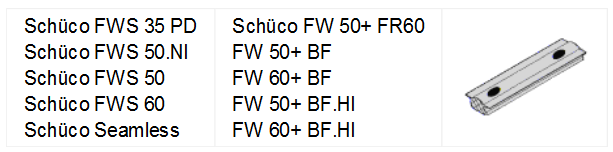

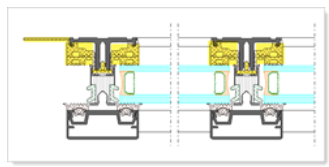

Schüco FWS 50/60:

Schüco ASE 60/80.HI sliding units as insert unit

Single-track and double-track versions of the Schüco ASE 60 and Schüco ASE 80.HI systems can be used in façade unit fields for the Schüco FWS 50 and Schüco FWS 60 systems in combination with adapter profiles (Art. No. 552 170, Art. No. 552 180, Art. No. 552 190). The Sliding and Lift-and-slide operating types (not TipTronic) can be selected. A combination with a spandrel safety barrier or a flyscreen is not possible for these insert units.

The unit parameters Type and Level threshold can be specified for the insert units in the Field properties dialog box.

Schüco FWS 50/60:

SI thermal insulation – Flat cover cap

As of this version, for units with SI thermal insulation, you can select the Flat cover cap entry for the Design, exterior unit parameter.

Schüco FWS 50/60:

Field ventilation not permitted with resistance classes RC 3/4 and FB 3/4

In the previous versions, in units with field ventilation (technical setting for Glazing rebate ventilation), it was possible to select resistance classes RC 3/4 and FB 3/4 in the unit parameters. As of this version, this combination is no longer possible for new items.

Please note:

If you have selected this combination in any of your existing items, you will receive a notification about this as of this version. Change your settings, if necessary.

Schüco FWS 50:

Mullion profiles Art. No. 536700, Art. No. 536710 and Art. No. 536730

As of this version, the profiles can be selected without a special activation code.

Schüco FWS 50, Schüco FWS 60, without resistance class:

Generation of spacer blocks (glazing bridges) changed

As of version 2022 R3, the glazing bridges (Art. No. 230401 to 230407) required for blocking and the accompanying screws have been generated for all resistance classes and for the Without resistance class in accordance with the K drawings.

According to updated fabrication documents, the use of these spacer blocks in units without a resistance class is now optional. Therefore, as of this version, the new Spacer block check box can be found in the technical settings under the Glazing group. By default, the check box is not checked. This setting only affects unit with the Without resistance class. For units with a selected resistance class, the glazing bridges will continue to be generated.

Please note:

This change affects existing items for which the Without entry has been selected as the resistance class.

Mullion/transom façades:

Seals for the transom joint with a continuous internal glazing gasket

As of this version, you can amend the technical settings so that the seals for the transom joint are also generated when the standard gasket without corners is used. To do this, find the new Standard without corners with seal entry for the Glazing gasket, inside property under the Gasket group.

Schüco AOC:

Inner gaskets – Specified in millimeters

As of this version, the calculated length of the glazing rebate gaskets and the building attachment gaskets is output in millimeters, instead of linear meters.

In addition, as a guide for cutting these gaskets, the cutting dimensions can now also be found in the following lists:

- Cutting list

- Cutting optimization