How to set up saw control files for Elumatec SBZ-122

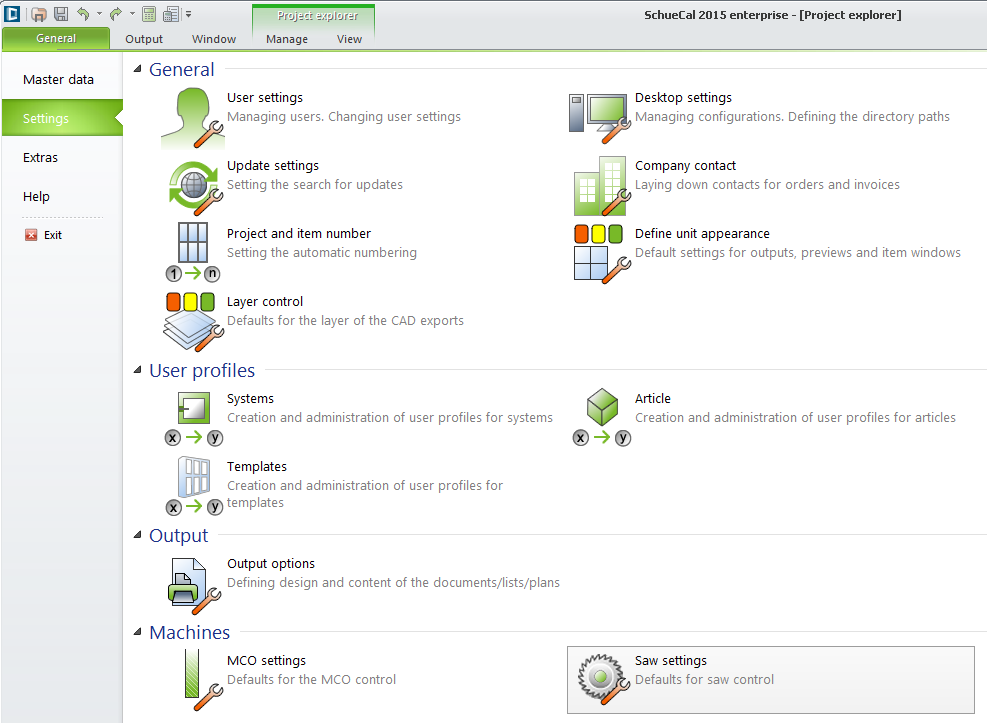

Go to General > Settings > Saw settings

In saw settings windows set up:

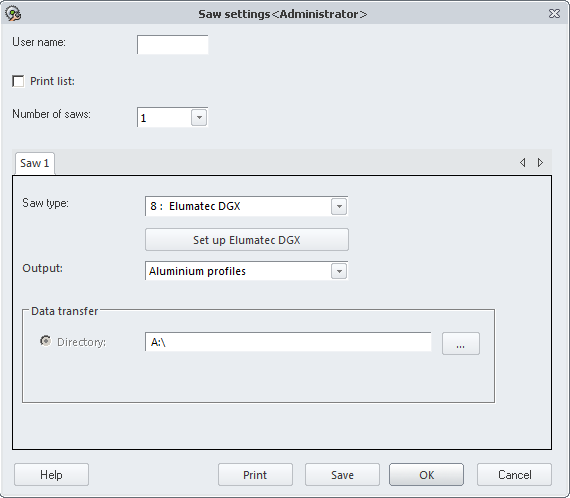

By entering a number in this field you can modify the generation of the first two digits of the file name.

If you leave the entry field empty, the file name is made up of the year and month, followed by a four-digit number. In addition, an extension is added as a description of the file type. E.g.: 01090000.dgx.

If you enter a two-digit user number (e.g. 45), these numbers replace the first two (year) digits of the file name: instead of 0190000.dat, it will be 45090000.dgx.

Print list

After data has been transferred, a dialog box will be displayed listing all the files generated. You can preview a list of the output saw files or print it directly.

Check the check box if you want to preview the list of the generated files for the output saw files or print it directly.

A quantity of 1 is entered by default. In this case, you can enter the saw type in the Saw type 1 tab.

If necessary, you can define additional default settings for a second saw type.

To do this, select 2 from the drop-down list. A second tab is displayed in which you can make specifications for Saw type 2.

When you start the output of the saw file, specify the saws for which the output is to be carried out in the Output options for saw control file dialog box. The clamping positions set are taken into account for the relevant saw in the saw files.

For the Cutting optimization list and Print label list, specify in the respective Output options the saws for which an output is to be carried out.

By selecting a saw, you define the output format. The various saw types are offered for selection in the drop-down list. If the saw you are using is not offered, select the saw type with the same output format as that of your saw.

Choose Elumatec DGX

Output

Aluminum profiles

Button …

Here, you specify the standard directory into which the generated saw files are to be saved. In the Output options for saw control file dialog box, you can enter a different directory path for each output if required. Furthermore, you can also enter a different file name there.

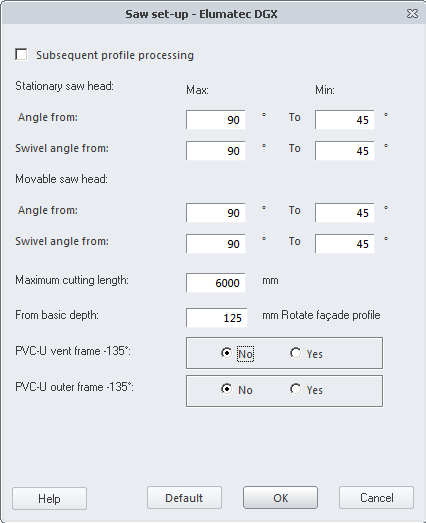

Click Set up Elumatec DGX

Note: When you output a Cutting optimization, the program checks whether a calculated angle of a profile cut can be processed with the saw. If this is not the case, the relevant angle of the profile cut is output as a 90-degree angle. This 90-degree angle is also saved in the Saw file.

Note: For profiles that were entered as user-defined articles, only the maximum dimension of the profile cuts can be output due to the absence of specifications for the profile width. Angles greater than 90 degrees are output as 90 degree angles.

Subsequent profile processing

The data in the DGX saw file can be output in a format that allows an Elumatec CNC machine to read the barcode on the labels generated on the Elumatec saw. For this, the saw file must be output together with the MCO file.

Note: For this output, the project and item numbers must be compatible with the “Code39” coding (alphanumeric, upper case letters only).

If you check this check box, the information required for the barcode is generated in the saw file.

Enter the maximum and minimum angles/swivel angles separately for the fixed and moving saw head.

Stationary saw head:

Angle from:

- In the Max field, enter the largest possible angle of the fixed saw head.

- In the up to: Min field, enter the smallest possible angle of the fixed saw head.

Swivel angle from:

- In the Max field, enter the largest possible swivel angle of the fixed saw head.

- In the up to: Min field, enter the smallest possible swivel angle of the fixed saw head.

Movable saw head:

Angle from:

- In the Max field, enter the largest possible angle of the moving saw head.

- In the up to: Min field, enter the smallest possible angle of the moving saw head.

Swivel angle from:

- In the Max field, enter the largest possible swivel angle of the moving saw head.

- In the up to: Min field, enter the smallest possible swivel angle of the moving saw head.

Maximum cutting length

Enter the maximum possible cutting length of the saw in millimetres.

From basic depth … Rotate façade profile

- Enter the basic depth in millimetres from which façade profiles should be rotated through 90 degrees.

The clamping position pre-set by the program for the relevant profiles is automatically adjusted.

In the program, particular clamping positions for each article are pre-set per saw type for the output of angles in the cutting optimisation and in the saw file.

If the cutting optimisation with profile section is output, you can see from the display of the profile section how the profile must be laid on the saw for the specified cutting angles.

The clamping positions defined by the program should be viewed as a “proposal”. The defaults result from the saw instructions in the fabrication manuals.