How to configure SchuCal Assembly time calculation and apply on model

Schucal has built in module for calculating Assembly labor time and cost. It can calculate each operation time generally, dynamic update with model dimensions.

User enter assembly operations as master data. User specify the calculation method for the time calculation and the calculation basis for the cost calculation.

Important: “Assembly time calculation” is different as “Additional labor costs”.

To do this it is necessary to configure two main parameters for each task: hourly rate and labor time.

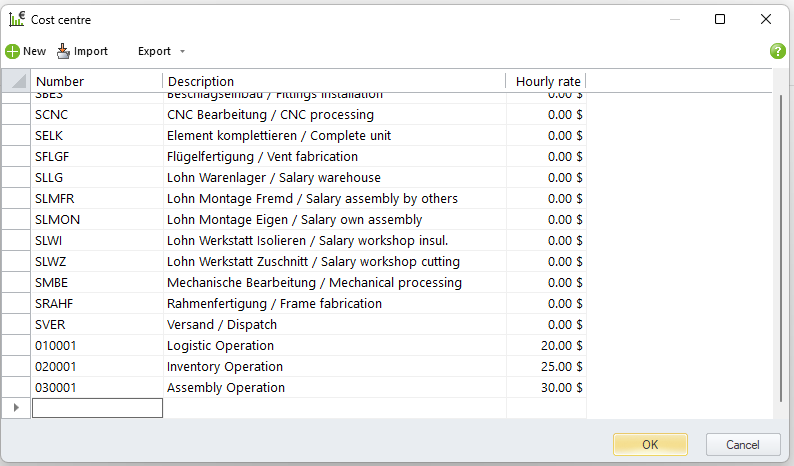

First it is necessary to set up hourly rate in Cost centre. Go to General > Master data > Cost Centre

There are some system default operations. You can edit or delete. You also can create as many positions as different labor cost groups you have. Add New position and enter Description and Hourly rate:

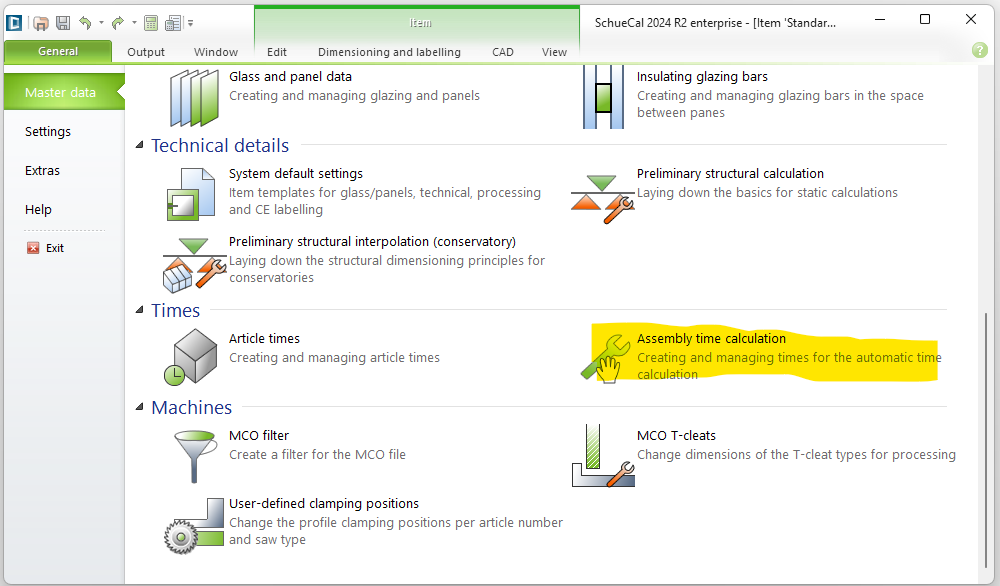

Now we can set up task timing rates. Go to General > Master Data > Assembly time calculation

Assemble time calculation master data is for setting up the basic operation. You also can group the operations based on your requirements. This data can be exported. You also can import the data.

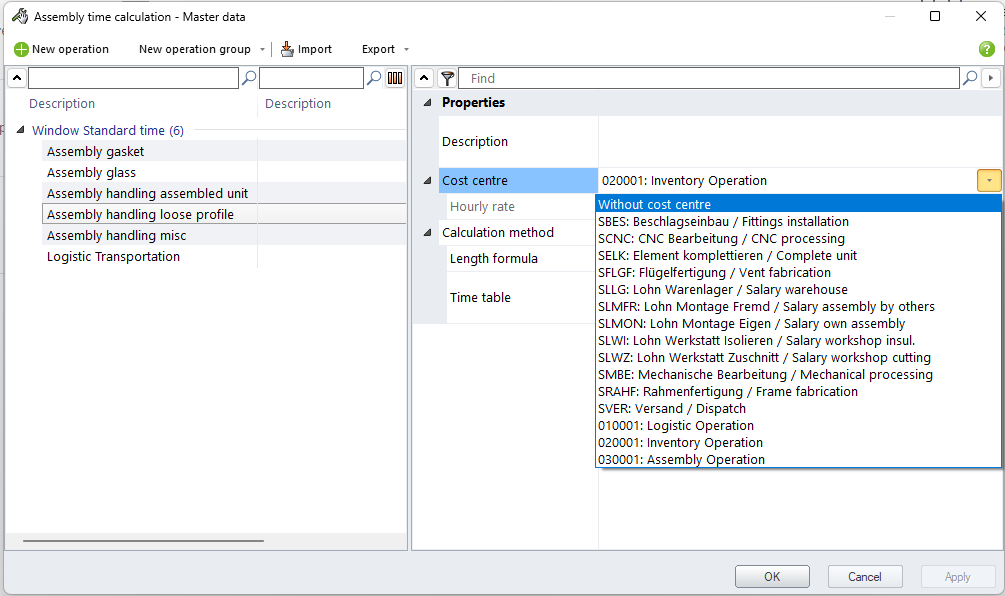

Click “New operation” to create an operation, edit the name and description.

Cost center: You can pick the cost type from the dropdown list of the selected operation. The data will be taken from “Cost center”. If you pick “Without cost center” from the dropdown list, the data will be taken from “Operating conditions” – “Assembly labor costs”.

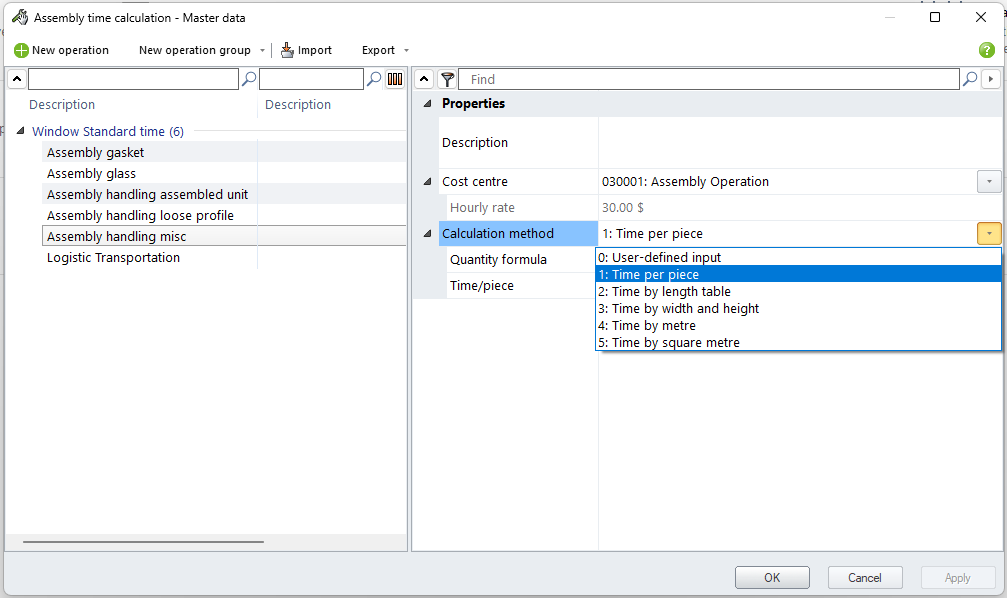

Calculation method: SchuCal provide 6 calculation method.

- 0: User-defined input: simply input a time. You cannot define any formula in this method.

- 1: Time per piece: Edit the “Quantity formula” and “Time/piece”. In the formula, the length unit is “mm”.

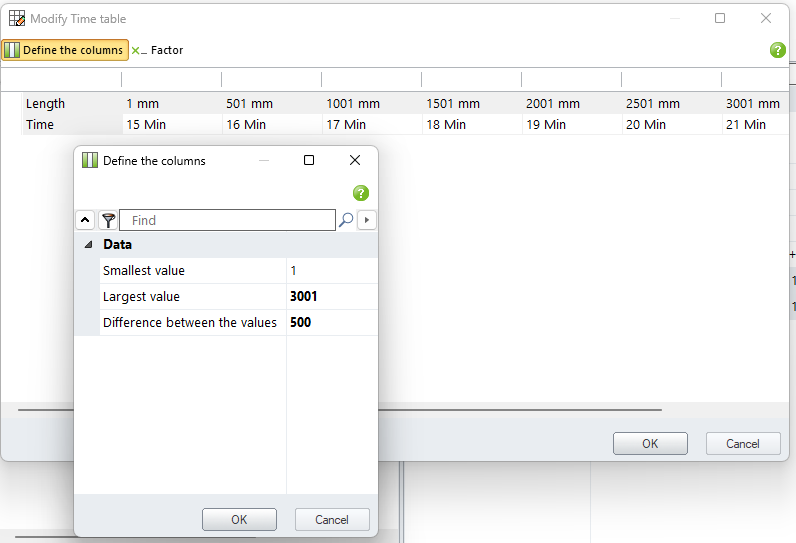

- 2: Time by length table: Edit the “length formula” and “Time table”. “Define the columns” edit the length table. Generating times automatically function is not available for this table. Need input the “Time” manually. “x_Factor” is based on the input “Time” times the “factor”, e.x. “Time”= 15 Min, “Factor” = 1.1, new “Time”= 16.5 Min.

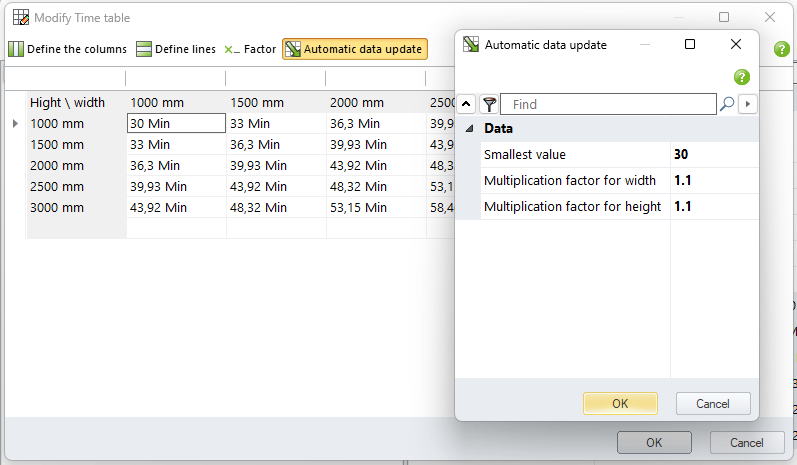

- 3: Time by width and height: Edit “Width formula” and “Height formula”. Similar as the “Time by length table”, define the columns, rows, and the factor. Generating times automatically function is available for this “Time table” by click “Automatic data update”. “Smallest value” is the top right corner time value. “Multiplication factor for width” is the factor for the rows. “Multiplication factor for height” is the factor for the column.

- 4. Time by meter: Edit the “Length formula” and “Time/m”. In the formula, the length unit is “mm”.

- 5. Time by square meter: Edit the “Area formula” and “Time/m2“. In the formula, the length unit is “mm”. 1 m2 = 10.764 ft2.

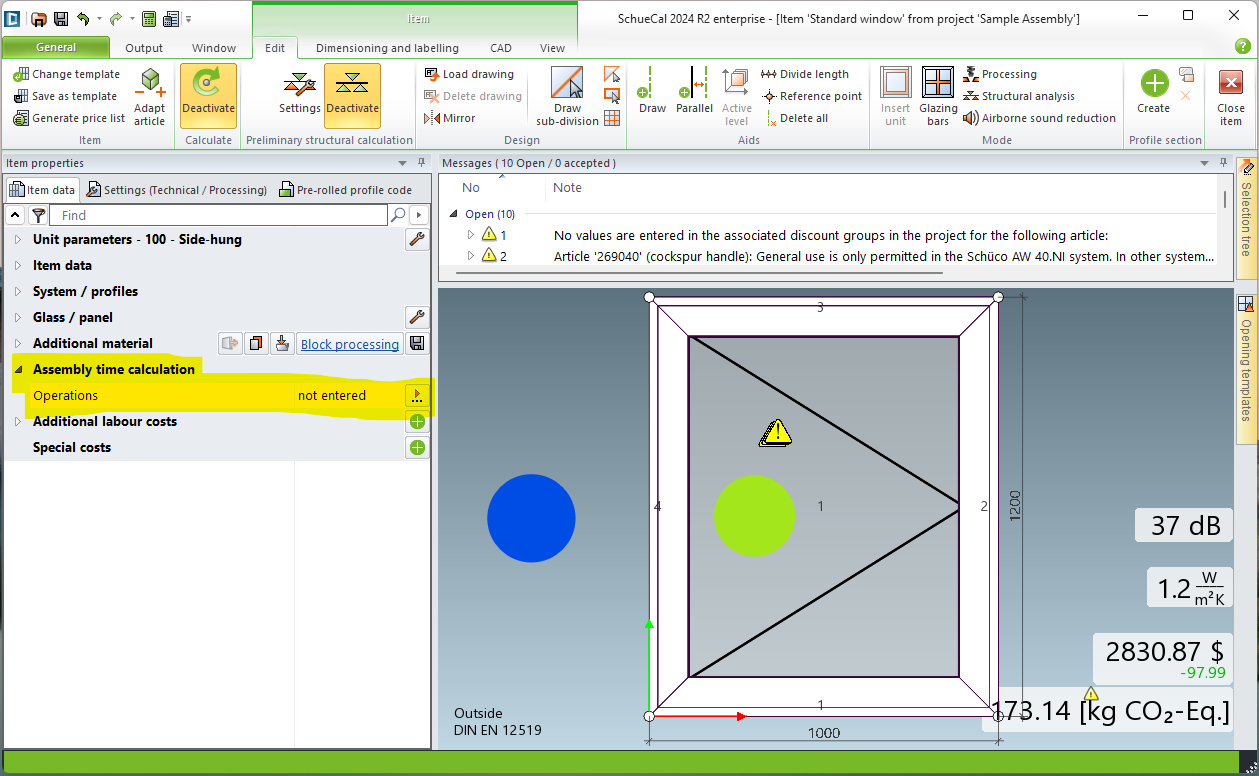

Assign operations to model: Once finish setting up all operations, you can assign the operations to the model.

Open the model and select the area you want to apply “Assembly time calculation”. Click outside of model (Blue dot) to select the whole model. Click field 1 (Green dot) to select field 1. You may have multiple fields in a model, depends on the model.

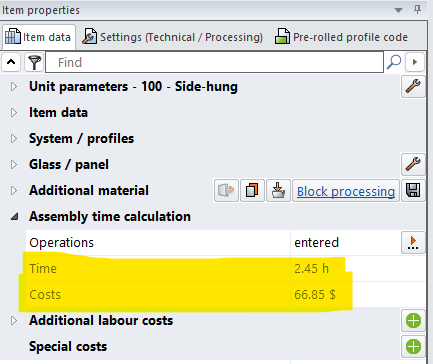

In “Item properties” – “Item data” – “Assembly time calculation”, Click “Operations” arrow button to the operation interface.

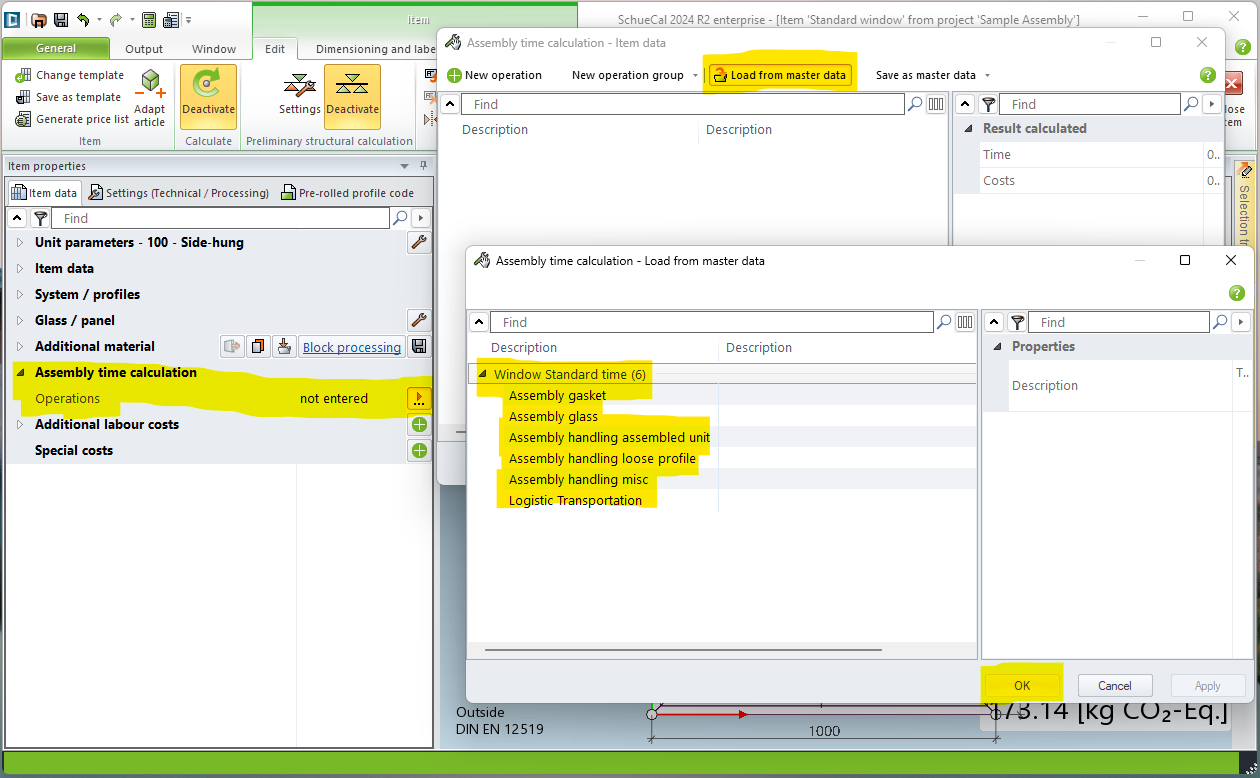

Click “Load from master data” to select the operations from the master data. Select the operations or the operation groups and click “OK”. Operation time and cost apply on the model.

Hint: Update operation master data will not affect the model has been assigned operation.

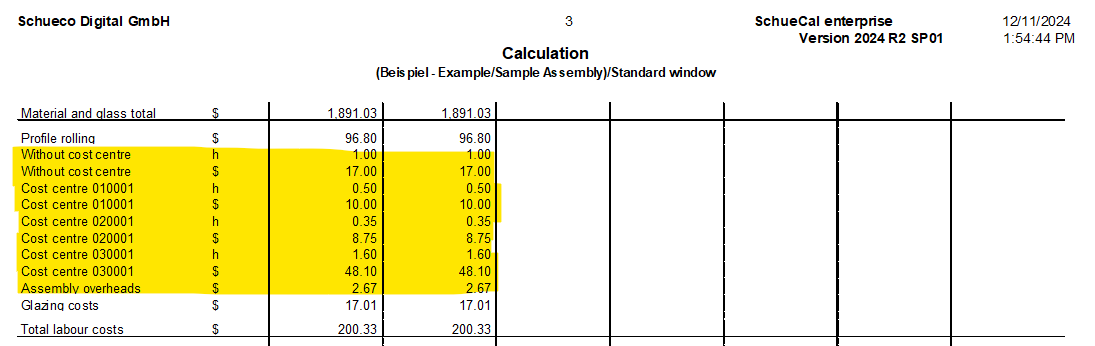

Times and cost will show on the “Item data” and calculation report.